Wide range

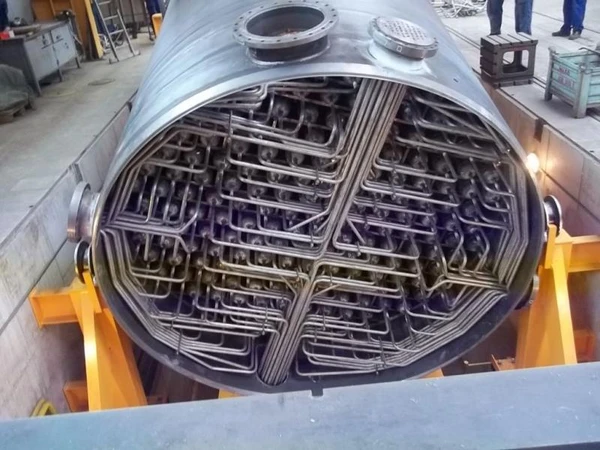

We design and manufacture:

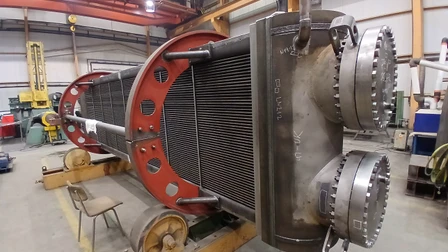

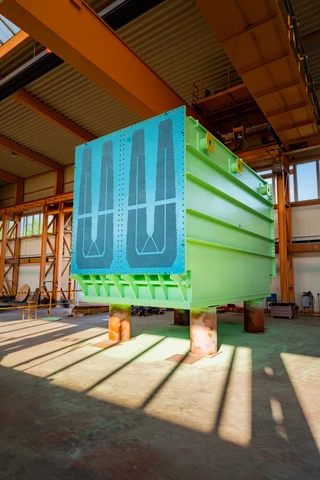

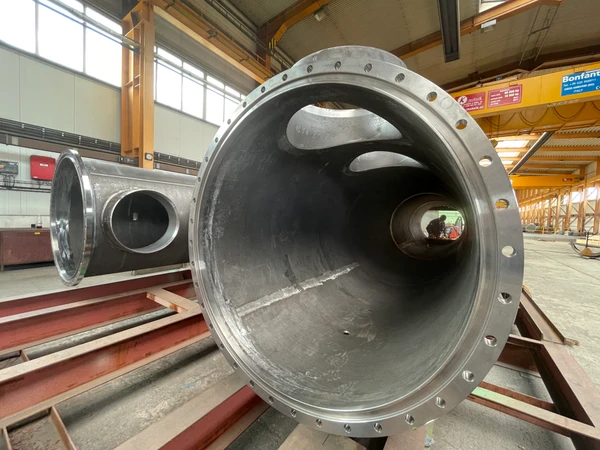

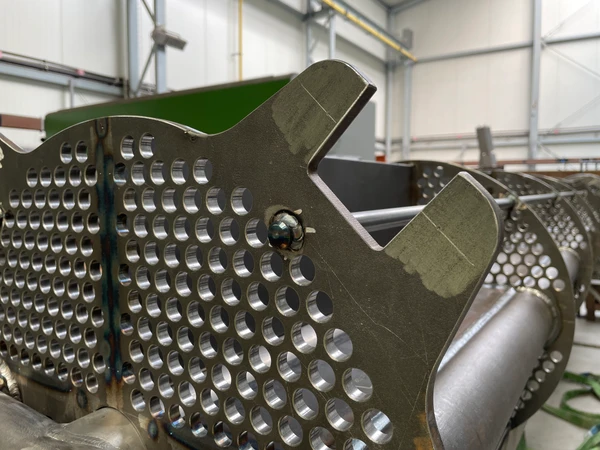

- steam condensers

- high-pressure, low-pressure and heating heaters

- oil and air coolers

- separators - steam heaters

- vaporisers and more

We will prepare a complete technical solution, including thermal-hydraulic calculations, strength calculations and detailed drawing documentation, see services our engineering team.